VZ ActiveVOC™ activated carbon is manufactured under stringent quality control, from scientific selected grades of coal-based carbon. It is activated through a comprehensive controlled process, and pre-treated with chemical reagents, specifically for removal of odorous gasses from vapour streams, in which hydrocarbons are present.

Hydrocarbons, H2S or Mercaptane odour removal process

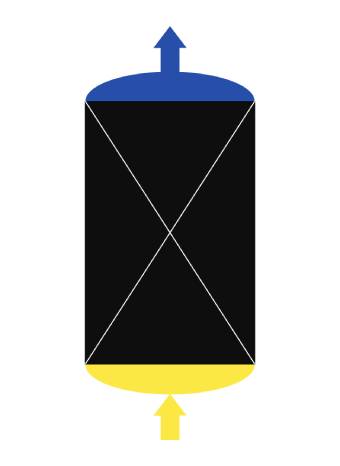

The Hydrocarbon, H2S or Mercaptan odour loaded gas is passed into the odour removal unit in the bottom of the reactor vessel. The odorous components are adsorbed onto the surface of the VZ ActiveVOC™ filter material, and the purified gas leaves the reactor from the top.

The VZ ActiveVOC™ filter material is designed for a lifetime of one to two years, depending on the concentration of odorous components in the inlet gas.

VOCZero OTF™ Odour Tank Filter

The Hydrocarbon, H2S or Mercaptan odour loaded gas is passed into the odour removal unit in the bottom of the reactor vessel. The odorous components are adsorbed onto the surface of the VZ ActiveVOC™ filter material, and the purified gas leaves the reactor from the top.

The VZ ActiveVOC™ filter material is designed for a lifetime of one to two years, depending on the concentration of odorous components in the inlet gas.

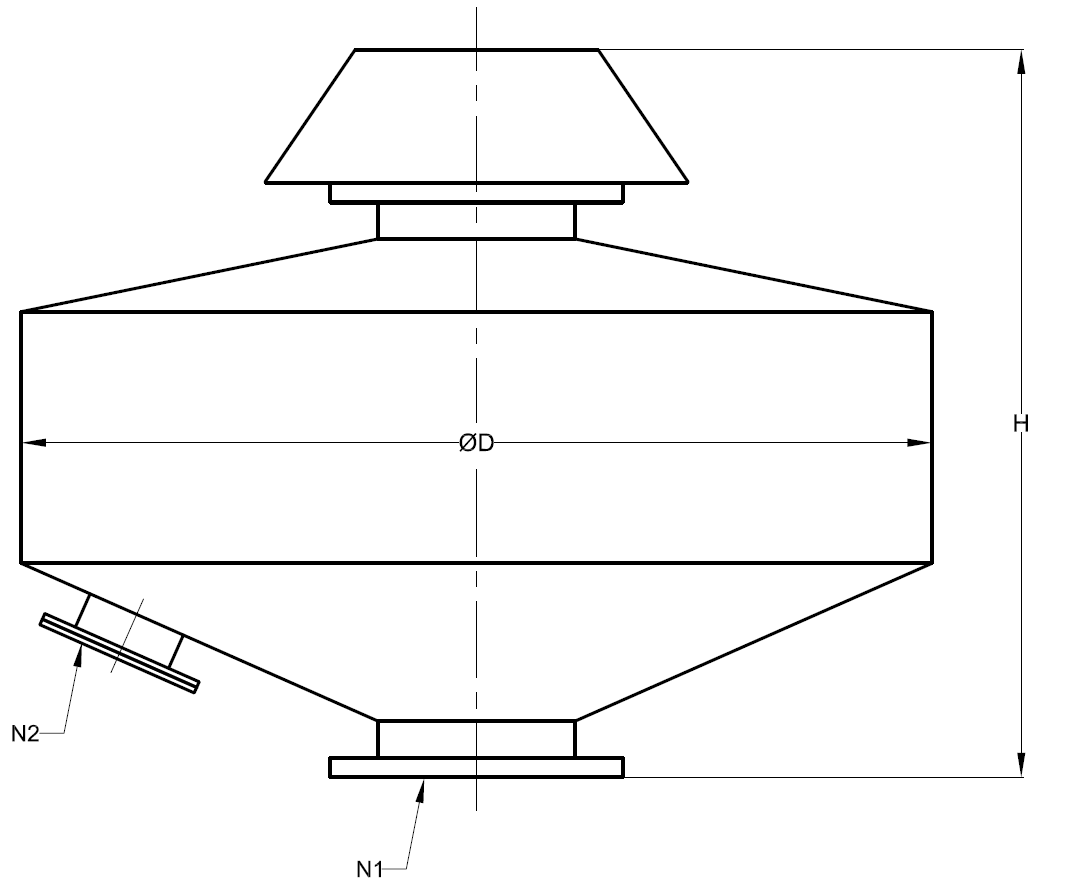

The Hydrocarbon, H2S or Mercaptan odour loaded gas is passed into nozzle N1. The odorous components are adsorbed onto the surface of the VZ ActiveVOC™ filter material, and the purified gas leaves the filter from the top through a vent cap.

The filters are designed to be installed directly onto the source of emission eg. storage tank or pit vent.

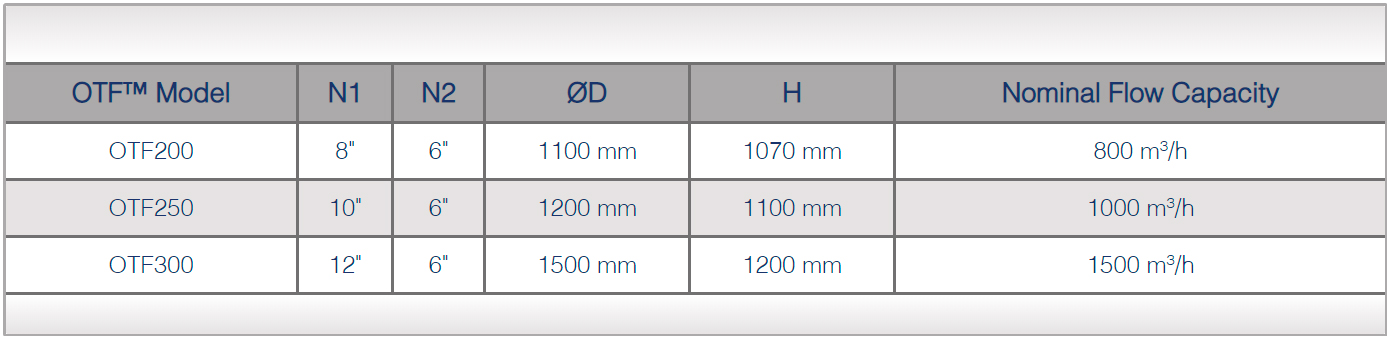

OTF™ Filters are available in 3 different sizes with inlet nozzle from 8″ to 12″